Turn your waste into value – efficiently and sustainably, with results you can be proud of. TANA machines and services offer superior versatility and the best user experience – value beyond profit. Our focus is on developing solutions and services that help you change the world of waste management.

Products

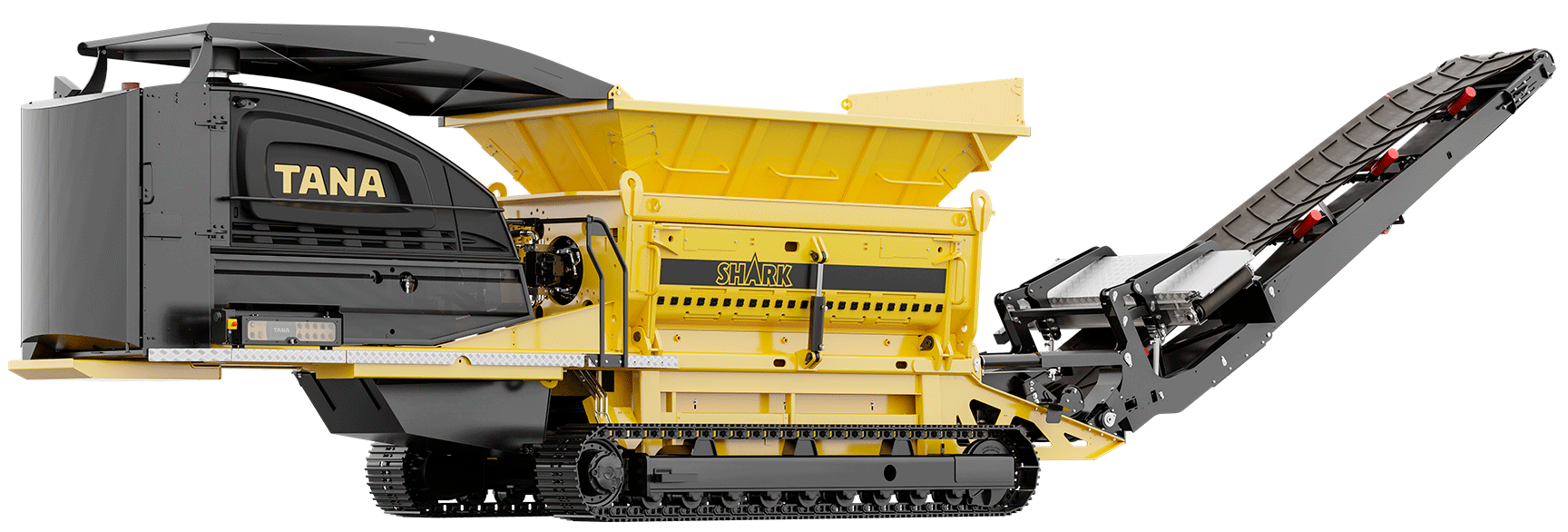

Shredder

Industrial waste shredder on tracks

The most versatile mobile waste shredder with excellent capacity and productivity. TANA Shark industrial waste shredders have multiple unique features.

You will get excellent performance with better fuel efficiency, lower machine operating costs and improved usability and serviceability. Robust machines have been built to last and maximize uptime.

Available models

Industrial waste shredder on semi-trailer

Easy to move. Choose diesel or 6 dB quieter electric engine with zero emission.

TANA shredder’s efficiency and unique versatility provide TANA owners with opportunities to increase profits and reduce costs.

Available models

Stationary industrial waste shredder

Stays put and guarantees zero emissions. 6 dB quieter.

TANA’s exceptional reliability, efficiency and productivity provide TANA owners with opportunities to gain more profits.

Available models

Compactor

Landfill compactors

Improved high-quality TANA landfill compactors – new models of H Series available now! TANA H Series landfill compactors are the result of long-term product development and proven solutions that create real benefits for your business.

Multiple new features make these landfill compactors to be even more powerful and reliable. Simply, these machines are able to handle waste on landfill sites in a cost-efficient way, providing better compaction and waste management capacity with lower operating costs.